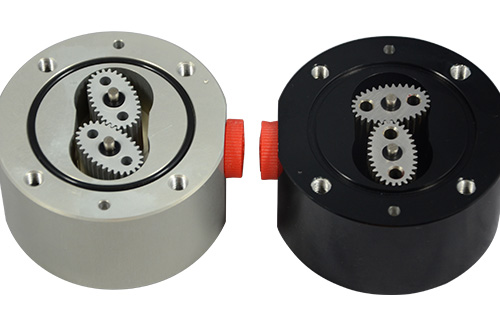

2 component plant gear flow sensor

email: porter@microflowmeter.com Shanghai JSNMicro Flow Meter CO.,LTD mainly produces super mirco flow meter,oval gear flowmeter ,coriolis mass flow meter,electromagnetic flow meter,piston flow meter,spurgear flow meter,gear pump,gear metering pump. We use high accurate CNCmachining center to make sure the high quality of our instruments and thecutting accuracy is 0.0001mm and has reached the world leading level. Forexample, the flow meter LSF40 of Japan OVAL, the flow range is 0.7~50L/H, butour CX-M5-AL is 0.3~60L/H with accuracy 0.5%F.S. We have applied many materialinto use on our flow meter,such as aluminium oxide, SS316L, PEEK,Ti ande soon.for different application and liquids.

2 component plant gear flow sensor

Withthe development of society, the state pays more and more attention to theprocess automation instrumentation industry. However, the Oval gear flow meter industryhas been in a vacancy and has been monopolized by major foreign brands such asMax, KRACHT, OVAL, etc. , People have long endured the expensive, longdelivery, the sale can not be resolved in time and so on, such as semiconductorchip cutting a set of equipment on the millions, once the instrument problems,loss unimaginable, the slayer saw these phenomena, Resolutely resigned assenior engineer in the position of Siemens, the establishment of ShanghaiJi-sheng Instruments Co., Ltd., with great concentration on research anddevelopment of gear flow meter. We have Oval gear flow meter has been awarded anumber of certificates, it is no exaggeration to say that Qishen production Ovalgear flow meter For example, many customers replace the OVAL LSF40 with ourCX-M5-AL because it costs less than half of the LSF40, but has twice the rangethan it does and has the same accuracy.

Shanghai JSN Micro Flow Meter Co., Ltd. is the second manufacturer ofmicro Oval gear flow meter in China. It is developed by Tu engineer (formerSiemens senior engineer) with independent intellectual property rights. Theproduction and processing equipment fully adopts Siemens CNC machining centerto ensure the minimum flow 0.1ml / min, which is rare in the world, theaccuracy of over 90% of peers. We can do more temperature 200C, the pressurecan be customized to 1000bar, many customers use it, but also unbelievable.Also domestic Most of the flowmeter use a year after the new calibration, butthe base depth meter after hundreds of conditions of medium test, the servicelife of more than 8 years, and without secondary calibration, since theestablishment of the base depth instrument Instrument determined to beworld-class flow meter, breaking the monopoly of international brands in themirco flow meter industry, so that customers can buy in the country realGerman-made quality flow meter.

2 component plant gear flow sensor

The CX-M and G series gearflow meters consist of a flow transmitter and a display. The oval gear flowmeter metering chamber of the flow transmitter has a pair of elliptical orcircular measuring gears. The gears and the measuring chamber form severalknown volumes. The cavity acts as a metering unit. Under the influence of thedifferential pressure between the inlet and outlet, the gear is driven torotate, and the imported liquid is continuously metered into the outlet aftermeasuring the metering chamber. At the same time, the sensor generates acorresponding electrical signal and sends it to the display section. Afterpartial treatment, the instantaneous flow and cumulative flow of the liquid canbe displayed.

2 component plant gear flow sensor

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

a. Thegear does not rotate: The gear is jammed by debris, the gear and cavity need tobe cleaned, and the filter is cleaned or replaced.

b. Thesmall flow error is too large: The flowmeter is installed in the wrongdirection, the best position goes up and down, or there are impurities to blockthe gear and need to be cleaned.

c. Theflow error is too large: The actual use flow range is less than or far greaterthan the flowmeter range. The corresponding flowmeter must be selected.

d. Noflow sensor signal: The gear is stuck or the circuit is connected incorrectlyor the circuit is damaged. The gear and cavity must be cleaned, or the circuitmust be correctly connected or replaced.

hotline

(86)021-57632436